Add to Cart

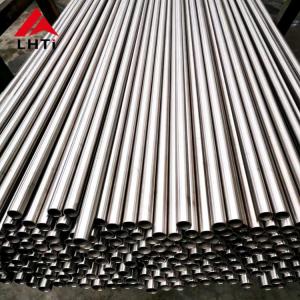

Heat exchanger tube OD25.4mm OD19.05mm ASTM B338 titanium pipe

1.Titanium tube Technical Requirements

| 1. | | Material Description | Titanium Seamless Tube |

| 2. | Material Specification | SB 338 Gr 2 (seamless) - Material shall comply the requirements as per ASME Sec-ll Part-B Edition - 2021. |

| 3. | | Manufacturing Process | As per material specification. |

| 4. | Delivery Condition | Ann ealed. |

| 5. | Size & Quantity | As per TEAM Purchase Order. |

| 6. | | Dimension$ | As per TEAM Purchase Order. |

| 7. | Tolerances | As per material/product specification. |

| 8. | Certificatio n | Material test certificates shall be to EN 10204 type 3.1 |

| 9. | Inspection by | TPIA. |

| 10. | if | All chemical composition shall be as per material specification. In addition, product Analysis shall be carried out and reported. |

| 11. | Mechanical Testing | All mechanical tests as per material specification shall be performed. |

| 12. | Heat Treatment Requireme nt | 1. Hnished Product As per delivery condition mentioned in sr. no. 4 above. |

| 13. | NDE & Other Tests | 1. Hydrotest- Hydro test shall be carried out as per material specification. Potable water shall be used for hydrotest. 2. Eddy current test- Shall be carried out as per material specification. 3. Ultrasonic Test- As per material specification. |

| 14. | Product Marking | As per material specification. |

| 15. | Packaging instructions | Tubes duly cleared by mills (and inspection authority) shall be protected against corrosion and shall be packed suitably to avoid damage during transit, handling & storage. |

| 16. | Repair Welding | Not permitted. |

| 17. | Intended Use | The material is intended to use in equipment designed as per ASME Section VIII, Division 1, Edition 2021. |

2.Heat exchanger tube application

3.Titanium alloy pipe specification

| Grade | N(%) | C(%) | H(%) | Fe(%) | O(%) | Ti | Other , max |

| 1 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.20 | ≤0.18 | Bal | ≤0.4 |

| 2 | ≤0.03 | ≤0.08 | ≤0.015 | ≤0.30 | ≤0.25 | Bal | ≤0.4 |

| Grade | Tensile Strength(min) | Yeild Strength(0.2% offset)) | Elongation(%) | ||||

| ksi | MPa | Min | Max | ||||

| Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 15 | 140 | 45 | 310 | ≥24 |

| 2 | 60 | 400 | 40 | 275 | 65 | 450 | ≥20 |

| Product name | Heat exchanger tube Titanium tube /pipe |

| Material | Titanium(Gr2) |

| Certificate | ISO9001:2015, TUV, EN10204.3.1 |

| Standard | ASTM B338 |

| Size | OD19mmxWT0.5-0.8mmx3000-12000mm OD25mmxWT1.0-1.2mmx3000-12000mm OD32mmxWT1.0-1.2mmx3000-6000mm OD38mmxWT1.0-1.2mmx3000-6000mm Or according customer’s requirement. |

| Technics | Rolled |

| Status | Annealed(M) |

| Type | Seamless Titanium Tube for heat exchanger, Titanium exhaust tube for automobile, titanium coil tube Welded Titanium Tube, |

| Application | 1)Power and chemical plant 2)Automotive components 3)sports 4)marine corrosion |

| Surface | Acid pickling, CNC lathe surface. |

4.Titanium tube Production process

5.Details picture in Workshop

| Material Grade | Status | Processing | OD(mm) | Wall thickness(mm) | |||||||||||

| 0.5 | 0.6 | 0.8 | 1.0 | 1.25 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 4.5 | ||||

| Gr1 Gr2 Gr7 Gr12 | Annealed (M) | Cold rolled | 10-15 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — |

| ﹥15-20 | — | ○ | ○ | ○ | ○ | ○ | ○ | ○ | — | — | — | — | |||

| ﹥20-30 | — | ○ | ○ | ○ | ○ | ○ | ○ | ○ | — | — | — | — | |||

| ﹥30-40 | — | — | — | — | ○ | ○ | ○ | ○ | — | — | — | — | |||

| ﹥40-50 | — | — | — | — | ○ | ○ | ○ | ○ | — | — | — | ||||

| ﹥50-60 | — | — | — | — | — | ○ | ○ | ○ | ○ | ○ | — | — | |||

| ﹥60-80 | — | — | — | — | — | — | ○ | ○ | ○ | ○ | ○ | ○ | |||

| Welded | 16 | ○ | ○ | ○ | ○ | — | — | — | — | — | — | — | — | ||

| 19 | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — | — | — | |||

| 25,27 | ○ | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — | — | |||

| 31,32,33 | — | — | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — | |||

| 38 | — | — | — | — | — | ○ | ○ | ○ | — | — | — | — | |||

| 50 | — | — | — | — | — | — | ○ | ○ | — | — | — | — | |||

| 63 | — | — | — | — | — | — | ○ | ○ | — | — | — | — | |||

| Welded-rolled | 6-10 | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — | — | — | ||

| ﹥10-15 | ○ | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — | — | |||

| ﹥15-20 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — | |||

| ﹥20-25 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — | |||

| ﹥25-30 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | — | — | — | — | — | |||

| Note: "○" indicates the specifications that can be produced | |||||||||||||||

ASTM B338 titanium tube

Used:Heat exchanger, condenser and various pressure vessels

Wall thickness:0.5mm to 4.5mm

Length:3000mm /6000mm and longger to 9000mm

Outside Diameters:10mm to 114mm

Wall thickness tolerance: +/- 10%

Length tolerance: +3.2mm

6. ASME SB388 Test as below

We provide following tests for Ti seamless and welded tubes

| Chemical Composition | Visual Inspect | Ultrasonic Testing | Current Testing |

| Flattening Testing | Flattening Testing | Pneumatic Test | Hydrostatic Test |

| Tensile | Yield | Hardness | Elongation |

7. Feel free to contact titanium alloy tube supplier