Add to Cart

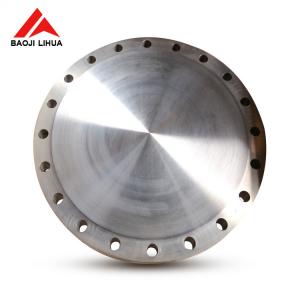

ASME B16.47 GR2 30" Titanium blind flange forged titanium flange

titanium flanges Type

1)Plate flat flange (PL),

2)welding neck flange (WN),

3)Slip-on flange (SO),

4)Socket welding flange (SW),

5)Threaded flange (Th),

6)Blind flange (BL ).

titanium flanges standard

American Standard :ASME / ANSI B16.5 / B16.47

(ASME / ANSI B16.36 for orifice flange ,ASME / ANSI B16.47 for large diameter steel flange

AWWA_C207-1994_is American Standard Steel Pipe Flange for Water Supply Engineering)

Japanese standard :JIS / KS B2220-2010

Germany (European Standard) :UNI EN1092-1

Russia : GOST 12821-80 ГОСТ 33259—2015

Titanium flange pressure

CL 150 300 400 600 900 1500 2500 Psi ,Etc

titanium flange Diameter

DN15 ~ 600mm

Titanium flange sealing face

raised surface (RF), Male and Female (MF), Tenon groove surface (TG), metal ring connection surface ,total four kinds.

titanium flange common size

DN15-DN2000 1/2 inch-36 inch

titanium flange application

Mainly used in petrochemical, medical and health, power, aerospace, military, fire protection, metallurgy, shipbuilding, gas,

and Environmental protection requires high pressure.

titanium flanges function

The flange, gasket and bolt are connected to each other as a detachable connection of a group of combined sealing structures.

Flange connection is an important connection method for pipeline construction.

The flange connection is easy to use and can withstand large pressures.

| products | titanium flange |

| Material Grade | Gr2, |

| Certification | ISO9001:2008, EN10204.3.1 |

| Standard | ANSI B16.47 |

| size | 30" |

| Pressure Class | CL600 |

| Technique | Forged and CNC Machined |

| type | BL |

| Flange surface | FF |

2. Chemical requirements

| N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Ti | |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5~3.5 | 2.0~3.0 | / | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | bal |

3. Tensile requirements

| Grade | Component | Tensile strength(min) | Yield strength(min) | Elongation(%) | ||

| ksi | M Pa | ksi | M Pa | |||

| 1 | Ta1 | 35 | 240 | 20 | 138 | 24 |

| 2 | TA2 | 50 | 345 | 40 | 275 | 20 |

| 5 | Ti6Al4V | 130 | 895 | 120 | 828 | 10 |

| 7 | Ti-0.2Pd | 50 | 345 | 40 | 275 | 20 |

| 9 | Ti-3Al-2.5V | 90 | 620 | 70 | 438 | 15 |

| 12 | Ti-0.3Mo-0.8Ni | 70 | 438 | 50 | 345 | 18 |

4. Mechanical Properties of ASTM B381 Titanium Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength | Elongation |

| Titanium Gr2 | 4.5g/cm3 | 1665℃(3030°F) | Psi- 49900, MPa- 344 | Psi-39900, MPa-275 | 20% |

| Titanium Gr5 | 4.43g/cm3 | 1632℃(2970°F) | Psi- 138000, MPa- 950 | Psi-128000, MPa-880 | 14% |

Test Items

Visual testing (VT)

Ultrasonic Testing (UT)--100%

Penetrant Testing/Dye penetrate (PT)